Setelah melakukan sedikit survei dan penelitian maka saya memutuskan untuk membuat camera gimbal dengan model sesederhana, sekecil mungkin dan seringan miungkin untuk bisa mengakomodasi camera internal dari ar.Drone 2 yg sudah ada. dan mungkin yg paling penting adalah… MURAH.… hehehe…

Soalnya kalau di total total beli komponen dibawah ini habis kisaran 300 ribu sampai 400 ribu, tergantung berapa banyak peralatan yg tidak harus beli (mungkin menggunakan yg ada atau pinjam)… hihihi…

bahan yg dibutuhkan adalah:

klik disini –> Bahan yg harus ada

1 ARDUINO PRO MINI 5V – [beli disini]

1 MODULE 3 AXIS ACCELEROMETER + GYRO SENSORS (3V-5V) – [beli disini]

2 Unit – Servo Ultra Micro Servo – [beli disini]

2 Trimmer Potentiometer (trimpot) 10k ohm

Plat alumuniun 0.5 mm secukup nya unt membuat arm gimbal

klik disini –> Bahan tambahan yg harus ada tapi bisa minta/pinjem

Jika semua bahan sudah ada maka rangkaiannya seperti ini:

Ketika dipasang di AR.Drone 2 tidak menggunakan FTDI, diganti pasokan 5v dari board AR.Drone 2.(Klik untuk Zoom)

Dalam rancangan saya memang saya buat tanpa PCB tambahan dan langsung solder kable untk mengurangi beban dari gimbal yg diusahakan kurang dari 50 gr.

Gimbal yg saya rancang ini hanya 2 axis (X ,Y) dengan 2 servo dan berat total hanya 30 gram bukan 3 axis (X, Y, Z) yg punya 3 servo berarti nambah sedikit lebih berat, karena ga cocok juga dan 3 axis kalau di pasang di AR.Drone 2 walau pun secara system gimbal ini mendukung 3 axis.

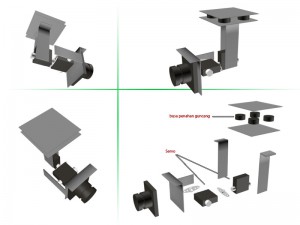

Dudukan servo dan camera pun pakai cara langsung lem besi saja spt ini:

Bagian coding menggunakan arduino ya… yg belum tahu caranya bisa langsung googling saja…

Buat testing gyro dan servo bisa pakai contoh ini…

http://www.4shared.com/rar/NLc5DkSCba/mpu6050_test.html

dan

http://www.4shared.com/rar/Yt5Liux3ce/Sweep_servo.html

dan berikut coding nya… dengan penyesuaian sesuai kebutuhan saya… jika masih perlu ada yg belum pas bisa di utak atik sendiri…

terdiri dari 2 file Arduino dan 1 file library… (silahkan klik untuk melihat script)

klik disini –> Ardrone2axis_gimbal_rev1.ino

/*

GYRO GIMBAL CAMERA AR.Drone

Berikut revisi ke 1 :

log perubahan ada di file kalman.h:

“merubah variable measure dan bias untuk

mengurangi noise getaran yg terlalu sensitif”

*/

#include <Servo.h>

Servo xservo; // create servo objects to control the servos

Servo yservo;

Servo zservo;

#include <Wire.h>

/* create Kalman filters objects to eliminates noise from gyro and accelerometer */

#include “Kalman.h”

Kalman kalmanX;

Kalman kalmanY;

Kalman kalmanZ;

uint8_t IMUAddress = 0x68;

/* IMU Data */

int16_t accX;

int16_t accY;

int16_t accZ;

int16_t tempRaw;

int16_t gyroX;

int16_t gyroY;

int16_t gyroZ;

/* Correction potentiometer pins */

int xpotpin = 1;

int ypotpin = 2;

int zpotpin = 3;

int xpotcor;

int ypotcor;

int zpotcor;

/* variable servo */

int moveX;

int moveY;

int moveZ;

int correctionX;

int correctionY;

int correctionZ;

/* Correction angle */

double accXangle; // Angle calculate using the accelerometer

double accYangle;

double accZangle;

double temp;

double compAngleX = 90; // Calculate the angle using a Kalman filter

double compAngleY = 90;

double compAngleZ = 90;

double kalAngleX; // Calculate the angle using a Kalman filter

double kalAngleY;

double kalAngleZ;

uint32_t timer;

// ———- VOID SETUP START ————– /

void setup() {

Serial.begin(115200);

xservo.attach(8); // Assign servo on pin 8 to the xservo object

yservo.attach(9); // Assign servo on pin 9 to the yservo object

zservo.attach(10); // Assign servo on pin 10 to the zservo object

Wire.begin();

i2cWrite(0x6B,0x00); // Disable sleep mode

if(i2cRead(0x75,1)[0] != 0x68) { // Read “WHO_AM_I” register

Serial.print(F(“MPU-6050 with address 0x”));

Serial.print(IMUAddress,HEX);

Serial.println(F(” is not connected”));

while(1);

}

kalmanX.setAngle(90); // Set starting angle

kalmanY.setAngle(90);

kalmanZ.setAngle(90);

timer = micros();

}

// ———- VOID SETUP END ————– /

// ———————- VOID LOOP START ————– /

void loop() {

/* Update all the values */

uint8_t* data = i2cRead(0x3B,14);

accX = ((data[0] << 8) | data[1]);

accY = ((data[2] << 8) | data[3]);

accZ = ((data[4] << 8) | data[5]);

tempRaw = ((data[6] << 8) | data[7]);

gyroX = ((data[8] << 8) | data[9]);

gyroY = ((data[10] << 8) | data[11]);

gyroZ = ((data[12] << 8) | data[13]);

/* Calculate the angls based on the different sensors and algorithm */

accYangle = (atan2(accX,accZ)+PI)*RAD_TO_DEG;

accXangle = (atan2(accY,accZ)+PI)*RAD_TO_DEG;

accZangle = (atan2(accZ,accY)+PI)*RAD_TO_DEG;

/* pembagi dibawah bisa di setting utk menyesuaikan rasio gerakan servo, lebih besar akan lebih pelan */

double gyroXrate = (double)gyroX/80.0;

double gyroYrate = -((double)gyroY/80.0);

double gyroZrate = -((double)gyroZ/80.0);

/* Calculate the angle using a Kalman filter */

kalAngleX = kalmanX.getAngle(accXangle, gyroXrate, (double)(micros()-timer)/1000000);

kalAngleY = kalmanY.getAngle(accYangle, gyroYrate, (double)(micros()-timer)/1000000);

kalAngleZ = kalmanZ.getAngle(accZangle, gyroZrate, (double)(micros()-timer)/1000000);

timer = micros();

/* baca value dari potensio meter untuk trim sumbu X,Y,Z */

xpotcor = (analogRead(xpotpin))*0.1;

ypotcor = (analogRead(ypotpin))*0.1;

zpotcor = (analogRead(zpotpin))*0.1;

correctionX = xpotcor;

correctionY = ypotcor;

correctionZ = zpotcor;

/* tentukan arah motor servo */

moveX = 200 – (kalAngleX) + correctionX;

moveY = 240 – (kalAngleY) + correctionY;

moveZ = 200 – (kalAngleZ) + correctionZ;

/* fungsi penggerak motor servo */

xservo.write(moveX);

yservo.write(moveY);

//zservo.write(moveZ);

/* debug print ke comm */

// Serial.print(moveX);Serial.print(” —- “);Serial.print(moveY);Serial.print(” —- “);Serial.print(moveZ);Serial.print(“\n”);

// delay(1); // The accelerometer’s maximum samples rate is 1kHz

}

// ———————- VOID LOOP END ————– /

// — FUNCTIONS START — /

void i2cWrite(uint8_t registerAddress, uint8_t data){

Wire.beginTransmission(IMUAddress);

Wire.write(registerAddress);

Wire.write(data);

Wire.endTransmission(); // Send stop

}

uint8_t* i2cRead(uint8_t registerAddress, uint8_t nbytes) {

uint8_t data[nbytes];

Wire.beginTransmission(IMUAddress);

Wire.write(registerAddress);

Wire.endTransmission(false); // Don’t release the bus

Wire.requestFrom(IMUAddress, nbytes); // Send a repeated start and then release the bus after reading

for(uint8_t i = 0; i < nbytes; i++)

data[i] = Wire.read();

return data;

}

// — FUNCTIONS END — /

[/stextbox] [stextbox id=”grey” caption=”I2C.ino” collapsing=”true” collapsed=”true”] //const uint8_t IMUAddress = 0x68; // AD0 is logic low on the PCBconst uint16_t I2C_TIMEOUT = 1000; // Used to check for errors in I2C communication

uint8_t i2cWrite(uint8_t registerAddress, uint8_t data, bool sendStop) {

return i2cWrite(registerAddress, &data, 1, sendStop); // Returns 0 on success

}

uint8_t i2cWrite(uint8_t registerAddress, uint8_t *data, uint8_t length, bool sendStop) {

Wire.beginTransmission(IMUAddress);

Wire.write(registerAddress);

Wire.write(data, length);

uint8_t rcode = Wire.endTransmission(sendStop); // Returns 0 on success

if (rcode) {

Serial.print(F(“i2cWrite failed: “));

Serial.println(rcode);

}

return rcode; // See: http://arduino.cc/en/Reference/WireEndTransmission

}

uint8_t i2cRead(uint8_t registerAddress, uint8_t *data, uint8_t nbytes) {

uint32_t timeOutTimer;

Wire.beginTransmission(IMUAddress);

Wire.write(registerAddress);

uint8_t rcode = Wire.endTransmission(false); // Don’t release the bus

if (rcode) {

Serial.print(F(“i2cRead failed: “));

Serial.println(rcode);

return rcode; // See: http://arduino.cc/en/Reference/WireEndTransmission

}

Wire.requestFrom(IMUAddress, nbytes, (uint8_t)true); // Send a repeated start and then release the bus after reading

for (uint8_t i = 0; i < nbytes; i++) {

if (Wire.available())

data[i] = Wire.read();

else {

timeOutTimer = micros();

while (((micros() – timeOutTimer) < I2C_TIMEOUT) && !Wire.available());

if (Wire.available())

data[i] = Wire.read();

else {

Serial.println(F(“i2cRead timeout”));

return 5; // This error value is not already taken by endTransmission

}

}

}

return 0; // Success

}

#define _Kalman_h

class Kalman {

public:

Kalman() {

/* We will set the variables like so, these can also be tuned by the user */

Q_angle = 0.001;

Q_bias = 0;

R_measure = 1;

angle = 0; // Reset the angle

bias = 0; // Reset bias

P[0][0] = 0; // Since we assume that the bias is 0 and we know the starting angle (use setAngle), the error covariance matrix is set like so – see: http://en.wikipedia.org/wiki/Kalman_filter#Example_application.2C_technical

P[0][1] = 0;

P[1][0] = 0;

P[1][1] = 0;

};

// The angle should be in degrees and the rate should be in degrees per second and the delta time in seconds

double getAngle(double newAngle, double newRate, double dt) {

// KasBot V2 – Kalman filter module – http://www.x-firm.com/?page_id=145

// Modified by Kristian Lauszus

// See my blog post for more information: http://blog.tkjelectronics.dk/2012/09/a-practical-approach-to-kalman-filter-and-how-to-implement-it

// Discrete Kalman filter time update equations – Time Update (“Predict”)

// Update xhat – Project the state ahead

/* Step 1 */

rate = newRate – bias;

angle += dt * rate;

// Update estimation error covariance – Project the error covariance ahead

/* Step 2 */

P[0][0] += dt * (dt*P[1][1] – P[0][1] – P[1][0] + Q_angle);

P[0][1] -= dt * P[1][1];

P[1][0] -= dt * P[1][1];

P[1][1] += Q_bias * dt;

// Discrete Kalman filter measurement update equations – Measurement Update (“Correct”)

// Calculate Kalman gain – Compute the Kalman gain

/* Step 4 */

S = P[0][0] + R_measure;

/* Step 5 */

K[0] = P[0][0] / S;

K[1] = P[1][0] / S;

// Calculate angle and bias – Update estimate with measurement zk (newAngle)

/* Step 3 */

y = newAngle – angle;

/* Step 6 */

angle += K[0] * y;

bias += K[1] * y;

// Calculate estimation error covariance – Update the error covariance

/* Step 7 */

P[0][0] -= K[0] * P[0][0];

P[0][1] -= K[0] * P[0][1];

P[1][0] -= K[1] * P[0][0];

P[1][1] -= K[1] * P[0][1];

return angle;

};

void setAngle(double newAngle) { angle = newAngle; }; // Used to set angle, this should be set as the starting angle

double getRate() { return rate; }; // Return the unbiased rate

/* These are used to tune the Kalman filter */

void setQangle(double newQ_angle) { Q_angle = newQ_angle; };

void setQbias(double newQ_bias) { Q_bias = newQ_bias; };

void setRmeasure(double newR_measure) { R_measure = newR_measure; };

double getQangle() { return Q_angle; };

double getQbias() { return Q_bias; };

double getRmeasure() { return R_measure; };

private:

/* Kalman filter variables */

double Q_angle; // Process noise variance for the accelerometer

double Q_bias; // Process noise variance for the gyro bias

double R_measure; // Measurement noise variance – this is actually the variance of the measurement noise

double angle; // The angle calculated by the Kalman filter – part of the 2×1 state vector

double bias; // The gyro bias calculated by the Kalman filter – part of the 2×1 state vector

double rate; // Unbiased rate calculated from the rate and the calculated bias – you have to call getAngle to update the rate

double P[2][2]; // Error covariance matrix – This is a 2×2 matrix

double K[2]; // Kalman gain – This is a 2×1 vector

double y; // Angle difference

double S; // Estimate error

};

#endif

Ga perlu copy-paste dari atas ya , bisa error krn ada tanda kutip yg berubah saat di pasang di web…

Jadi… 3 File project diatas bisa langsung didownload aja di :

http://www.4shared.com/rar/epXk1FZYce/Ardrone2axis_gimbal_rev1.html

ini merupakan file Revisi 1 dg perubahan untuk mengurangi noise dari vibrasi AR.Drone…

Letakkan pada folder yg sama ya… lalu pangil dengan Arduino IDE…

Setelah semua selesai dan harus dipasang di AR.Drone maka jangan lupa melepas Modul FTDI basic programernya ya… apalagi kalau itu FTDI pinjaman… hahaha…

lalu sambungkan VCC pin yg tadi terhubung denga FTDI ke Motherboard AR.Drone2 anda di PIN 9 dan GND ke pin 10 (lihat gambar dibawah)

tapi dengan catatan bahwa USB port di AR.Drone 2 harus terhubung dengan memory stick atau GPS module sehingga AR.Drone 2 akan mengalirkan arus 5V nya….

Jangan lupa share kalau ada yg lebih baik ya…!!

PS: buat yg masih bingung gimbal camera itu buat apa, bisa cari di youtube dengan kata kunci Camera Gimbal… Salah satunya spt video ini yg bisa membedakan hasil video yg menggunakan gimbal dan yg tidak…

dan ini hasil video komparasi nya… yg menggunakan gimbal dan yg tidak…

Nah jelas kaan…yg ga pakai gimbal lebih banyak guncangan nya…

yang pasti ini project ini masih banyak kurang nya… tapi semoga bisa jadi inspirasi ya…

PS: Apa ada yg punya ide bagus bagaimana mengilangkan jelly effect selain balancing propeller… mungkin penggunaan silikon atau lainnya…??